News: Suppliers

4 March 2021

Inseto supplies K&S Asterion wedge bonder to CIL

Inseto (UK) Ltd of Andover, UK (a distributor of equipment and materials to the semiconductor, microelectronic & advanced technology sectors) has supplied Custom Interconnect Ltd (CIL) with a Asterion large-diameter wire/ribbon wedge bonder made by Singapore-based chip assembly & packaging equipment and materials supplier Kulicke & Soffa Industries Inc (K&S) for use in the production of wide-bandgap (WBG) semiconductor-based power modules and the assembly of battery packs.

The Asterion is to play a crucial role in two major electric vehicle (EV) projects in which CIL is extensively involved.

In the first project, CIL is engaged with BMW on APC15@FutureBEV to maximize the potential for future battery electric vehicle (BEV) systems. The project is one of 10 projects by the Advanced Propulsion Centre (APC) in its latest round of Government and industry funding for low-carbon emissions research.

In the second project, CIL is the project lead on GaNSiC – a project that stems from the UK Research and Innovation’s (UKRI) ‘Driving the Electric Revolution’ challenge and brings together CIL and Compound Semiconductor Applications Catapult (CSA Catapult, a not-for-profit organization headquartered in South Wales). It is set to develop novel ways of applying silver sinter pastes to WBG semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN) devices, to optimize their thermal coupling and solve complex power module assembly challenges.

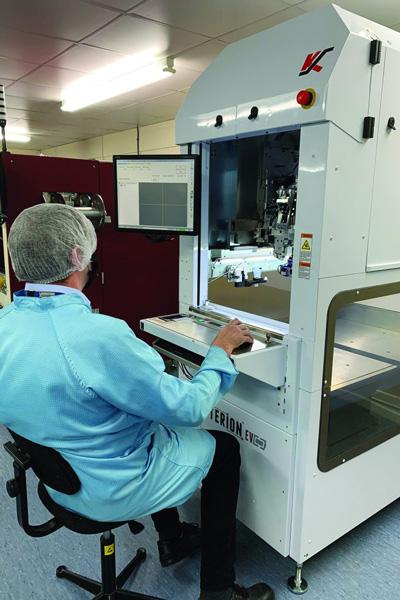

Picture: Kulicke & Soffa Asterion wedge bonder installed at CIL’s new BEV facility.

Picture: Kulicke & Soffa Asterion wedge bonder installed at CIL’s new BEV facility.

“Because of the high currents EV power modules handle, both projects require the placement of heavy-gauge wire or ribbon, of between 150μm and 600μm diameter or width compared to fine-wire bonding, which tends to be about 25μm,” says CIL’s managing director John Boston.

SiC-based power module designs are aiming to switch up to 800VDC and handle up to 600A. “You need heavy gauge, but heavy-gauge wire bonding of wide-bandgap materials is a relatively new technology,” notes Boston. “More than ever before, there’s a need for collaboration and trust within the industry. Also, with keeping costs low such an imperative in the automotive sector, the use of advanced manufacturing tools likely to produce the best results is essential, particularly when some vehicle manufacturers are demanding zero defects and stipulating that reworks are not allowed.”

As an electronic solutions provider, CIL has the largest independent ‘chip and wire’ facility in the UK and its microelectronics packaging facility is regarded as being at the forefront of the EV power revolution, says Inseto.

“In addition to APC15@FutureBEV and GaNSiC, we’re the manufacturing partner on many other EV projects, plus we have many customers in the aerospace sector – active under initiatives like the More Electric Aircraft and the All-Electric Aircraft,” Boston says.

The K&S Asterion is located in CIL’s BEV facility, and joins an automatic die bonder and high-pressure silver sinter press (both of which are for the packaging of WBG materials) and a scanning acoustic microscope used to detect voids. The Asterion will also be used in the manufacture of EV batteries, specifically for bonding between cells and busbars/plates.

Inseto is exclusive distributor for Kulicke and Soffa’s range of wire bonding and die bonding equipment & materials in the UK, Ireland and Nordic regions.

Established in 1986 and ISO9001:2015, ISO13485:2016 (Medical) and AS9100D (Aerospace) certified, CIL is also on the path to ISO/TS 16949:2009 (Automotive) certification. The firm has transitioned from a conventional electronics manufacturing services (EMS) company into an electronic solutions provider and currently manufactures some of the most complex mission-critical electronic assemblies in the UK. A combination of six SMT lines, 3D AOI, Flying probe test and laser depanelling enables it to manufacture complex SMT PCB assemblies. CIL also has one of the largest independent die and wirebond facilities in the UK. Three automatic die bonders, and six automatic wire bonders and various encapsulation systems are available. It is now entering a WBG power module manufacturing era to support both UK- and EU-based companies deploy SiC- and GaN-based assemblies.