News: LEDs

15 December 2021

Hot performance from InGaN red μLED

University of California Santa Barbara (UCSB) and Google in the USA have reported on the efficiency and high-temperature performance of indium gallium nitride (InGaN) micron-scale ‘red’ light-emitting diodes (μLEDs) [Panpan Li et al, Appl. Phys. Lett., v119, p231101, 2021].

The research builds on the previous work of UCSB [www.semiconductor-today.com/news_items/2021/sep/ucsb-090921.shtml]. The μLEDs demonstrate relatively high ~3% efficiencies and low 0.05nm/K red-shift with temperature. The researchers comment: “This demonstrates the robustness of InGaN red μLEDs up to high temperature, with a much-improved stability over conventional AlInGaP red μLEDs.”

In fact, aluminium indium gallium phosphide (AlInGaP) devices suffer from increasing surface recombination effects sapping efficiency as devices shrink to the micron level. This is attributed to a high surface recombination velocity in the AlInGaP material system.

There has been increasing interest in μLEDs as the basis for general lighting, display and automobile headlights. In the display sector, extending the AlInGaN technology from the blue (450-485nm) sector, through green (500-565nm) and red (625-750nm) is particularly attractive. Full-color LED displays could see deployment in watches, augmented reality, virtual reality, and ultra-large televisions.

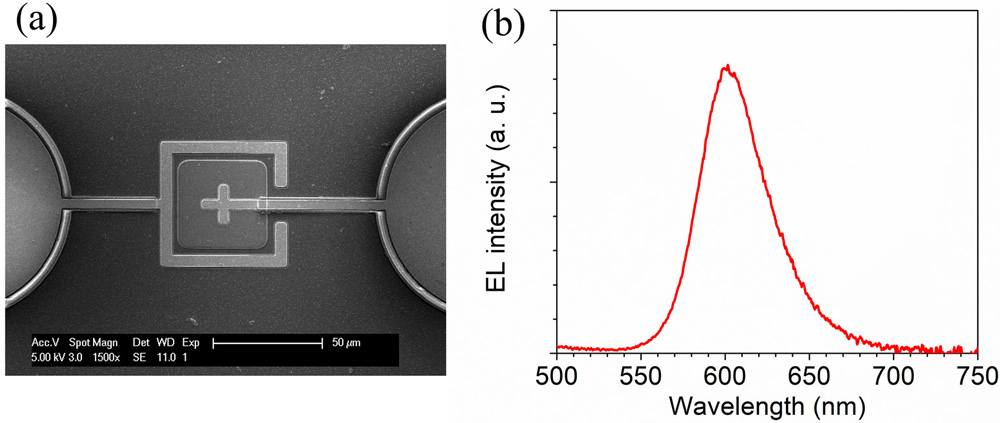

Figure 1: Scanning electron microscope image of μLED and (b) emission spectrum at 20A/cm2.

On the other hand, the high indium content required for longer-wavelength emission in the green and red sectors becomes increasingly difficult. Indium is less reactive with nitrogen than the Al, Ga components, meaning that growth temperatures need to be reduced, resulting in lower crystal quality, impacting efficiency. The lattice mismatch between high-indium-content InGaN relative to GaN also creates piezoelectric fields in LED structures, which reduce electron-hole recombination into photons (the ‘quantum-confined Stark effect’).

The researchers used metal-organic chemical vapor deposition (MOCVD) on patterned sapphire substrate to create the epitaxial material for the μLEDs. The light-emitting active region consisted of five InGaN quantum wells separated by AlGaN cap/GaN barrier layers.

The μLED fabrication (see link above for schematic and more details) consisted of 100nm indium tin oxide (ITO) transparent contact deposition, reactive-ion mesa etch, omnidirectional reflector formation from silicon dioxide/tantalum pentoxide layers, atomic layer deposition (ALD) of silicon dioxide mesa sidewall passivation, and evaporation of aluminium/nickel/gold for contacts/pads.

At 20A/cm2 room-temperature injection the 40μmx40μm devices emitted light with a peak at 600nm wavelength and 48nm full-width half-maximum (FWHM). The researchers say that this suggests a high crystal quality in the active region of the device. The peak is more strictly in the orange range (590-625nm).

As the temperature of the μLED was raised the wavelength red-shifted at a rate of 0.05nm/K, arriving at ~605nm at 400K. The researchers compare this very low shift with reports for InGaN on Ga2O3, 0.085nm//K, and for 630nm AlInGaP devices, 0.137nm/K. “InGaN-based red μLEDs are promising candidates for high-temperature wavelength-stable lighting sources,” the team comments.

The forward voltage decreased at a higher rate than expected as the temperature increased (4mV/K). However, above 380K, the device became leaky at low current injection. The ideality (n) of the μLED was 6.7 at 300K, falling to 5.0 at 360K. The leaky behavior at higher temperatures pushes the ideality up again. The researchers comment: ”An ideality factor larger than 2 can be caused by trap-assisted tunneling, carrier leakage, and other sources of imperfect injection. Therefore, the high ideality factors observed here indicate non-ideal transport, possibly caused by significant defect-assisted processes. The reduction in n at high temperature indicates an improvement in injection processes.”

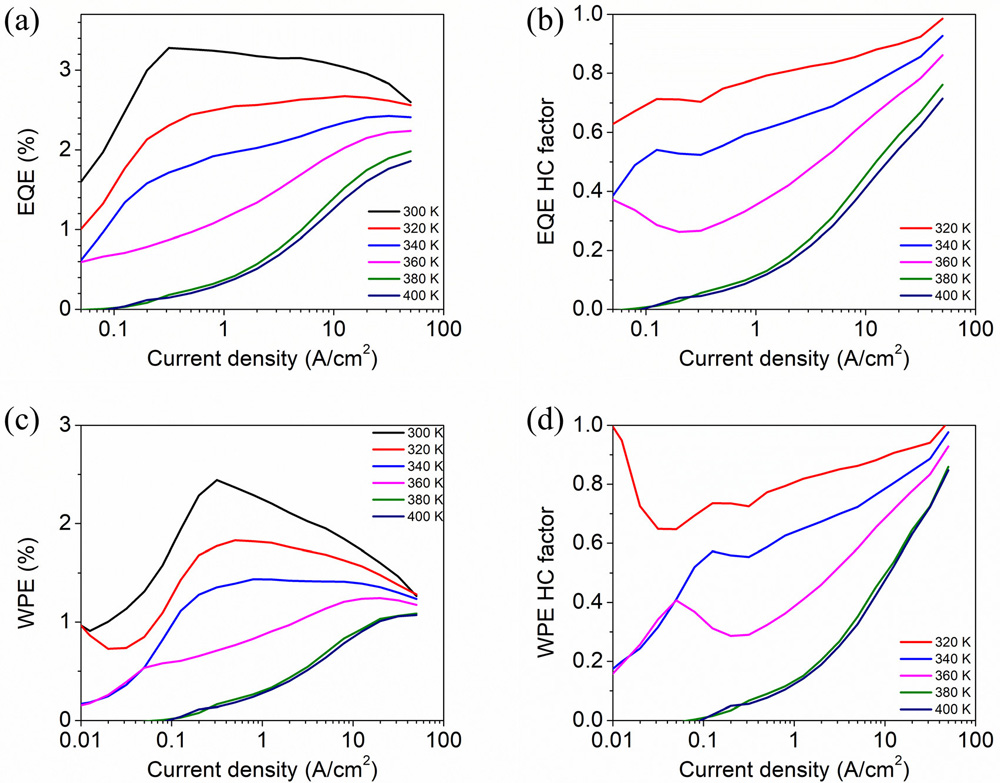

The external quantum efficiency (Figure 2) reaches 3.2% at room temperature, exceeding previous reports of 0.56% for red InGaN μLEDs. The value is also comparable with a reported 4.8% for a 32μm red μLED produced using AlInGaP materials. The relatively flat EQE behavior was attributed to the imperfect injection suggested by the high ideality. Droop sets in at ~3A/cm2 injection.

Figure 2: Temperature-dependent (300-400K) (a) EQE, (b) EQE HC factor, (c) WPE, and (d) WPE HC factor versus current density.

As the current injection increases the EQE relative to that at 300K, the ‘hot-cold’ (HC) factor, increases. At 50A/cm2 injection the EQE HC factor reached 0.85 at 360K. “The HC value at 360K is similar to that of commercial blue InGaN LEDs, suggesting that this high-temperature robustness is a general property of the InGaN material system,” the team writes.

Combining the electrical and EQ efficiencies to give the wall-plug efficiency (WPE), the researchers found a peak value of 2.4% at ~3A/cm2 injection. The WPE HC factor at 400K and 50A/cm2 was 0.85. “The higher WPE HC factor (0.85) at 50A/cm2 compared to the EQE factor (0.72) at 400K is attributed to the reduction in voltage at high temperature,” the researchers explain.

The researchers compare their EQE HC factors to those for regular-size AGaInP red LEDs: 0.55 for 388/298K, and 0.4 for 400K/300K, reported by different groups. The team comments: “It is expected that the HC factor would be even lower in AlInGaP red μLEDs, since the impact of non-radiative recombination increases significantly for small sizes. Therefore, InGaN red μLEDs exhibit a smaller thermal droop compared to AlInGaP red μLEDs.”

InGaN red µLEDs Red LEDs InGaN AlInGaP red µLEDs MOCVD

https://doi.org/10.1063/5.0070275

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.