News: LEDs

8 September 2020

Wafer-scale micro-LEDs transferred onto adhesive film for planar and flexible displays

Researchers at the Guangdong Institute of Semiconductor Industrial Technology (GISIT), the University of Tokyo, and Foshan Debao Display Technology Co Ltd have recently developed a tape-assisted laser lift-off transfer (TALT) technique, addressing the industry’s problems of massive chip transfer and heterogeneous integration of micro-LED for high-resolution display purposes [Zhangxu Pan et al, ‘Wafer-Scale Micro-LEDs Transferred onto an Adhesive Film for Planar and Flexible Displays’, Advanced Material Technology, https://doi.org/10.1002/admt.202000549].

Recognized as a next-generation display technology in the display industry, micro-LEDs have many advantages such as higher brightness, lower power consumption, longer lifetime, higher resolution and faster response speed compared with conventional liquid crystal display (LCD) and organic light-emitting diode (OLED) display technologies. They are therefore expected to have very good application prospects in wearable electronic devices, outdoor displays and augmented reality/virtual reality (AR/VR) head-mounted displays.

However, the volume production of high-resolution micro-LED display devices currently faces many challenges. Among them, how to quickly and accurately transfer and integrate millions of micro-LED chips onto the drive circuit is a major hurdle to be overcome. Although a variety of transfer technologies for micro-LEDs have been proposed, there is still ample room for improvement in their transfer speed and placement accuracy. In addition, most of these transfer technologies are focused on the optimization of the chip transfer technology itself, but less attention is paid to their compatibility with subsequent bonding processes.

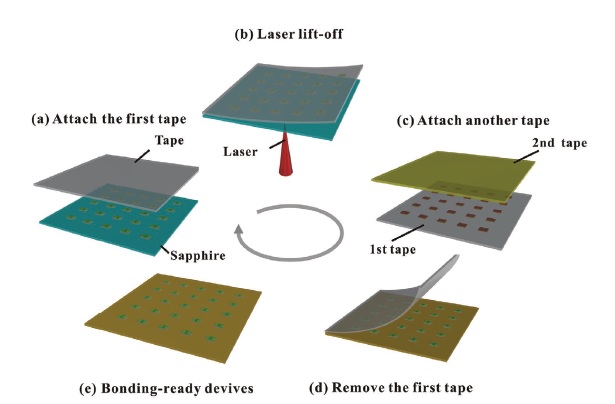

The joint teams have exploited the merits of both laser lift-off and tape transfer to fabricate wafer-level thin-film micro-LEDs. The novel TALT technique for fabricating thin-film micro-LEDs transferred to a temporary adhesive substrate is shown in Figure 1. An adhesive tape is laminated onto the micro-LED arrays on a sapphire substrate [Figure 1(a)]. The sapphire substrate is then taken off by laser lift-off (LLO). As a result, wafer-scale micro-LED arrays are then released to the first adhesive tape [Figure 1(b)]. Before flip-chip bonding to a driver board, micro-LEDs must be turned upside down. This is achieved by attaching another tape with stronger adhesion to the full LED arrays on the first tape [Figure 1(c)]. Because of the stronger adhesion, micro-LEDs can be released to the second tape. This is achieved by simply peeling away the first tape [Figure 1(d)]. Now, transferrable thin-film micro-LEDs, which are particularly suited to flip-chip bonding, are ready [Figure 1(e)].

Figure 1. Working procedure of TALT technique for wafer-level micro-LED transfer.

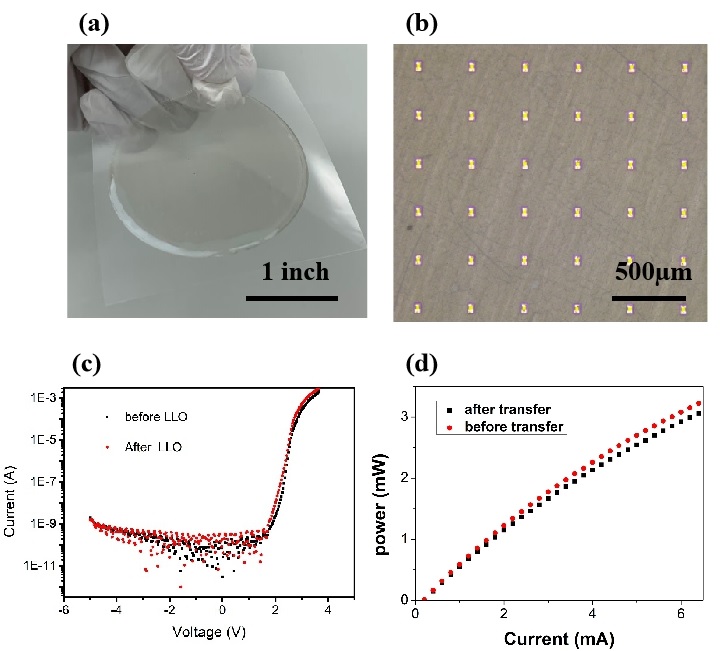

The resulting wafer-level micro-LED thin film is shown in Figure 2. The results in Figures 2(a) and (b) clearly show that a very high yield of micro-LED lift off (up to 99.9%) can be achieved under optimized LLO conditions. Both the optical and electrical tests suggest that the device before transfer and after transfer shows minimal degraded device performance [Figures 2(c) and (d)]. The researchers believe that this method has the potential for wafer-scale production, and can even be scaled up to larger-size wafers.

Figure 2. Wafer level micro-LEDs transferred to an adhesive tape, and their electrical and optical performance.

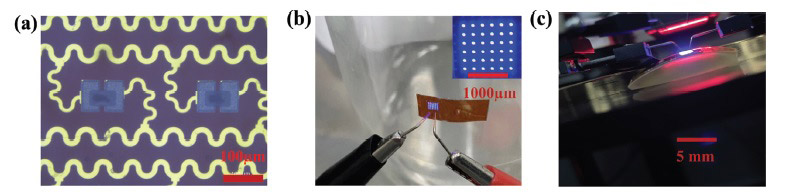

The researchers also particularly emphasize that the TALT technology is suitable not only for wafer-level transfer of micro-LEDs but also for flip-chip bonding for good electrical connection. Indeed, the researchers have further demonstrated both rigid and flexible micro-LED prototypes with convincing device performances, based on the TALT technique and the bump-less bonding process that the same joint team has developed. Representative flexible micro-LED devices are shown in Figure 3.

Figure 3. Flexible micro-LED display prototypes.

The researchers reckon that this technique paves the way for fast assembly of micro-LEDs with high yield and excellent placement accuracy. The method is also promising for fabricating high-resolution micro-display devices for potential applications in areas such as VR/AR headsets, wearables and mini-projectors.