News: Suppliers

20 May 2020

LayTec’s reports use of EpiTT FaceT for process control of laser facet passivation in MBE

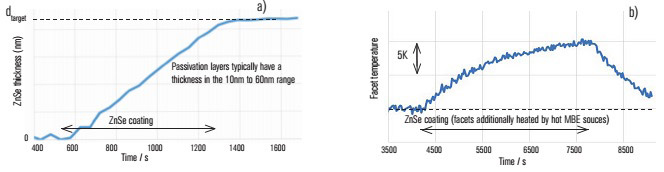

After in January reporting the use of its EpiTT FaceT temperature metrology system for improving the yield of facet coating processes in large production molecular beam epitaxy (MBE) systems for high-power gallium arsenide (GaAs)-based lasers, LayTec AG of Berlin, Germany is now sharing the latest data on the EpiTT FaceT’s performance: beyond facet temperature sensing in the range between room temperature and 400°C it has added real-time in-situ thickness sensing of the nanometer-scale zinc selenide (ZnSe) facet coating layers.

Picture: Monitoring ZnSe facet coating on a stack of GaAs-based edge-emitting lasers.

Figure 1(a) shows the increase in ZnSe thickness (d) on the facets, as measured with a resolution better than 0.5nm by short-wavelength reflectance during the MBE process. Figure 1(b) demonstrates the response of facet temperature to heat transfer from the MBE sources during coating.

LayTec adds that this comprehensive and precise process control is vital for preventing catastrophic optical damage (COD) in the laser devices.

LayTec’s EpiTT FaceT chosen by high-power laser maker for yield improvement