News: Suppliers

19 March 2020

LayTec’s new InspiRe in-situ tool used for monitoring perovskite formation

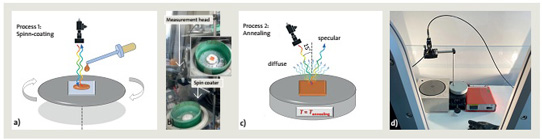

The efficiency of perovskite photovoltaics (PVs) has recently increased tremendously (according to the US National Renewable Energy Laboratory). In a tandem configuration at Germany’s Helmholtz-Centre Berlin (HZB), even the best silicon solar cell was surpassed (29.1%) using wet-chemical low-cost methods. Despite this progress, many challenges remain for this technology. In-situ metrology system maker LayTec AG of Berlin, Germany says that its new InspiRe (Figure 1) system applies high-speed in-situ reflectance measurements for monitoring perovskite thin-film formations during spin-coating and subsequent annealing.

Figure 1: Experimental setup for spin-coating (a, b) and annealing (c, d) of perovskite thin films, illustrating the concept of the particular measurements (a, c) and the actual setups (b, d). LayTec’s InspiRe metrology system was employed for monitoring both key processes for perovskite thin-film formation.

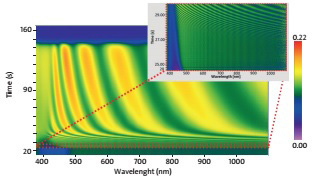

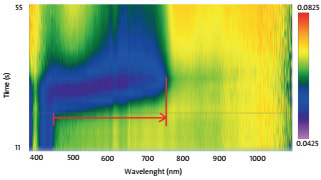

In collaboration with professor Norbert Nickel’s group at HZB, LayTec designed the InspiRe in-situ metrology system, which was applied to monitor both spin-coating (Figure 2) and annealing (Figre 3). Gathering data at a time resolution on the millisecond scale allows resolving of the kinetics and phase formations during film formation.

|

|

| Figure 2: Spin-coating: examplary color plot obtained during perovskite deposition. The inset zooms into the first 5s after starting the rotation. | Figure 3: Annealing: example of a color plot obtained during perovskite annealing. The red arrow marks the shift of the absorption edge. |

While spin-coating, the absorption behavior and the thinning of precursor solution is monitored. The absorption edge (i.e. band gap) of the deposited perovskite film is derived directly during annealing. Spectral changes during annealing indicate ‘over-annealing’ after the desired bandgap has been achieved.

This methodology, for the fist time, allows the systematic study of film formation during two crucial process steps for identifying optimization routes and for implementing a rigid quality control scheme for upscaling and industrialization.

In an upcoming publication, the HZB researchers will present their analysis of the perovskite formation based on measurements employing LayTec’s InspiRe metrology system.