News: Suppliers

19 June 2020

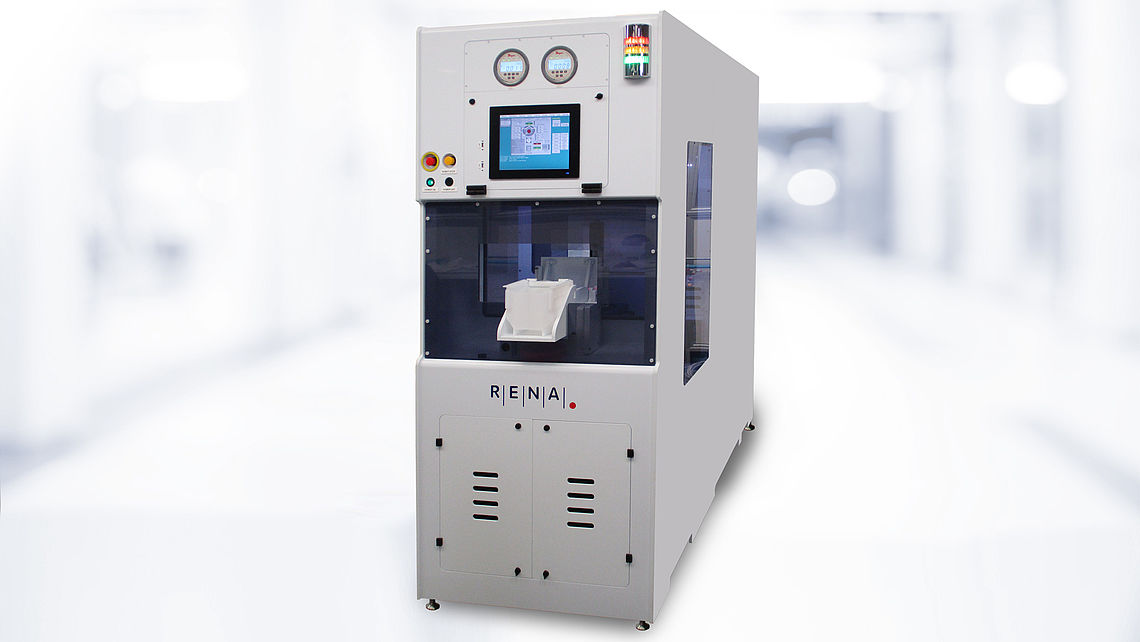

RENA launches single-wafer processing system for wet clean, etch and strip

Known for proven immersion and batch spray technology, RENA Technologies has added to its portfolio of wet processing platforms by launching the Inception single-wafer platform, which enables the transition from R&D to pilot-line production and is capable of all semiconductor wet processes such as clean, etch, strip and dry.

The first Inception has already been shipped to a major compound semiconductor customer that will utilize its capabilities in an acid clean process.

“If all you have is a hammer, everything looks like a nail,” says Ed Jean, CEO of RENA Technologies NA. “Batch immersion, batch spray and single-wafer tools all have their place in the wet process world. Most equipment suppliers however offer a one-size-fits-all approach, trying to ‘hammer’ your application into the only platform they offer. With the addition of the Inception single-wafer tool to our product lineup, RENA provides the appropriate platform for any wet clean, etch or strip application,” he adds.

“The Inception single-wafer platform provides our customers, who perform tests in beakers and pie plates, the consistency to develop a process of record and automate their process,” says Heath Phillips, RENA Technologies NA Spray Product Manager.

Features of the Inception single-wafer tool include:

- FEoL front-end-of-line (acid) and BEoL back-end-of-line (solvent) processing applications;

- automated wafer handling (manual load optional);

- wafers up to 200mm diameter and masks up to 7 x 7;

- dual moving spray arms with separate chem lines;

- stationary bottom spray nozzles for DI and N2;

- etch uniformity exceeds batch systems;

- standard dual-tank design providing multi-step processing (4-tank optional);

- single or dual load ports;

- low utilities consumption;

- small footprint – 36” width x 83” height x 76” length;

- highly flexible software enabling rapid process development.