| Home | About Us | Contribute | Bookstore | Advertising | Subscribe for Free NOW! |

| News Archive | Features | Events | Recruitment | Directory |

News

14 September 2010

UCSB achieves CW operation of AlGaN-cladding-free nonpolar lasers

University of California Santa Barbara (UCSB) has succeeded in producing continuous wave pure-blue (461nm) nonpolar (m-plane) laser diodes without using aluminum gallium nitride (AlGaN) cladding [Kathryn M. Kelchner et al, Appl. Phys. Express, vol3, p092103, 2010].

AlGaN cladding is used in commercial laser diodes since such layers have a suitable refractive index contrast to allow the indium gallium nitride or gallium nitride (InGaN/GaN) waveguide layers to confine the optical field and create the conditions for stimulated (laser) emission. However, there are a number of problems arising from its use.

Thick layers of AlGaN are slow to grow and have a large lattice mismatch with the underlying gallium nitride crystal structure. The lattice mismatch tends to result in cracking of the layer as the thickness of the AlGaN layer increases. Also, p-type doping with magnesium is less effective than for pure GaN, leading to higher operating voltages and energy loss. Further, the aluminum precursors used to grow AlGaN can cause parasitic reactions in some reaction chambers.

The focus of present nitride laser diode development is for full-color display and mobile projector systems. Nitrides already provide the blue component, and much work is underway to extend this capability into green wavelengths.

Desired qualities for such laser diodes are spectral purity, thermal stability, efficiency and compactness. Traditional nitride laser diodes grown on c-plane nitride substrates suffer from high internal electric polarization fields due to strain-dependent effects. These piezoelectric polarization fields reduce the recombination efficiency for the electron-hole transitions that produce light. Also, there is a severe blue-shift in the emission wavelength as the injection current increases. The polarization fields can be eliminated by using nitride layers grown in the nonpolar m-plane direction.

Reducing the Al-content in nitride LDs has increased the maximum output power and reduced catastrophic optical damage by expanding the optical field in the transverse direction. Reliability studies in arsenide (As) laser diodes show that Al-free devices resist facet degradation and oxidation effects. The UCSB researchers suggest that similar improvements in manufacturability and reliability could be seen for high-power InGaN/GaN laser diodes.

UCSB has been developing AlGaN-cladding free nitride LDs on nonpolar (m-plane) and semipolar substrates from its first reported device in 2007.

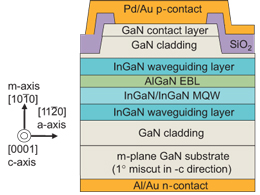

The UCSB laser diode (Figure 1) has an active region consisting of a three-period In0.18Ga0.82N/In0.03Ga0.97N multiple quantum well (MQW) with 5nm wells and 10nm barriers. A 10nm electron-blocking layer (EBL) of p-AlGaN was put on top of the MQW to reduce electron overshoot into the p-contact region. Such overshoot leads to non-radiative emission and reduced laser efficiency.

Figure 1: Schematic cross-section of UCSB ridge-waveguide laser diode.

Figure 1: Schematic cross-section of UCSB ridge-waveguide laser diode.

The 50nm separate confinement heterostructure (SCH) waveguide layers on each side of the active region (Figure 1) consisted of In0.08Ga0.92N, doped appropriately with silicon (n-type) and magnesium (p-type). The doped cladding consisted of GaN, 4μm thick on the n-side and 500nm on the p-side. A heavily doped 100nm p-contact layer of GaN completed the structure.

The layers were grown on free-standing low-defect-density m-plane GaN substrates manufactured by Japan’s Mitsubishi Chemical Corp using atmospheric-pressure metal-organic chemical vapor deposition (AP-MOCVD). Layer compositions were determined from x-ray diffraction measurements on calibration samples grown separately.

The epitaxial material was processed into 4μm-wide, 500μm-long ridge waveguide laser diodes oriented parallel to the c-direction of the nitride semiconductor crystal structure. Mirror facets on the ends of the laser cavity were produced by coating with high-reflectivity coatings of alternating quarter-wavelength layers of silicon dioxide and tantalum pentoxide (front power reflectivity ~0.85, back ~0.90).

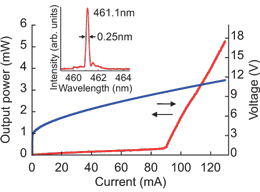

Testing of the device was carried out using on-wafer probing with a temperature-controlled stage. At 20°C, the threshold current for continuous wave (CW) operation (Figure 2) was 87mA, corresponding to a density of ~4.1kA/cm2. The emission wavelength was 461.1 nm, with a full width half maximum (FWHM) of 0.25nm. The threshold voltage was 9.8V. The slope efficiency was ‘characteristically low’, at 0.3W/A.

Figure 2: Dependence of output power and voltage on current under CW conditions. Inset: CW lasing spectra.

Figure 2: Dependence of output power and voltage on current under CW conditions. Inset: CW lasing spectra.

The threshold density was lower than previous AlGaN-cladding-free devices and comparable to more tradition m-plane laser diodes with AlGaN cladding. The researchers attribute the improvement to optimized growth conditions and the use of substrates that were intentionally misoriented by 1° towards the [000-1] c-direction. Such misorientation tends to improve the growth process in terms of surface morphology and lateral InGaN uniformity.

Measurements in the spontaneous emission region (below threshold) give a blue-shift of the emission wavelength of 9nm/decade. The researchers comment that this value is smaller than the blue-shift reported for c-plane devices emitting at a similar wavelength and can be attributed to the elimination of the ‘quantum confined Stark effect’ (QCSE) that arises from piezoelectric polarization fields.

The characteristic temperature of the shift in threshold current (T0) was determined to be 156K by using pulsed operation (1microsec pulse, 0.1% duty cycle) to avoid self-heating effects. This value compares with other nitride pure-blue laser diodes that fall in the range 141-170K. Spectral measurements show a thermally induced red-shift of 0.05nm/K. The estimated thermal impedance of the device was ~60K/W.

Apart from using UCSB facilities, the researchers also used funding from the US National Science Foundation (NSF) and the Visible InGaN Injection Lasers (VIGIL) program run by the US Defense Advanced Research Program Agency (DARPA).

See related items:

Low threshold for m-plane nitride semiconductor lasing

Yet another angle on nitride laser diodes

AlGaN-cladding-free semipolar laser nears green

![]() Search: AlGaN-cladding-free nonpolar blue lasers InGaN GaN GaN substrate

Search: AlGaN-cladding-free nonpolar blue lasers InGaN GaN GaN substrate

Visit: http://apex.ipap.jp

For more on Lasers: Latest issue of Semiconductor Today

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.