- News

10 July 2019

Laser diode market to grow to $14bn in 2029, with direct-diode lasers contributing $2bn

The global market for laser diodes and direct-diode lasers will reach $14bn by 2029, with direct-diode lasers contributing $2bn, forecasts technology consulting firm IDTechEx Research in its report ‘Laser Diodes & Direct Diode Lasers 2019-2029: Technologies, Markets & Forecasts’ by analyst Dr Nilushi Wijeyasinghe.

Evolution of laser diodes and diode bars

Technology advances have enabled lasers to progress from specialist technical instruments to a diverse range of markets. Specifically, while becoming the most widely available laser technology, the average power of laser diodes has increased significantly during the past three decades, and their average price per watt has fallen exponentially. Consequently, laser diodes are displacing some established laser and non-laser technologies, while enabling entirely novel optical technologies. Mature applications of laser diodes include data storage, data communication and the optical pumping of solid-state lasers. In contrast, material processing and optical sensing are examples of rapidly evolving market segments with many emerging applications.

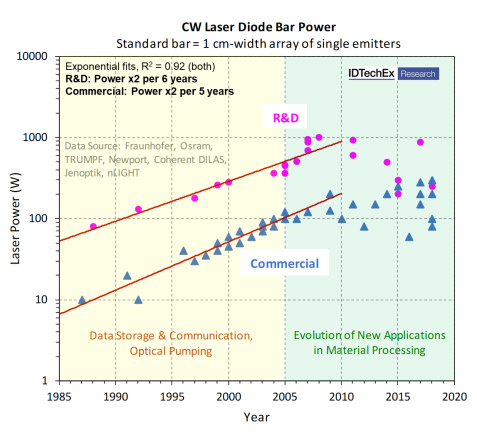

Picture: The increase in diode bar power contributed to the development of direct diode lasers and enabled new applications in material processing. Ongoing evolution of diode laser technology includes the improvement of infrared beam quality for precision engineering and the development of novel visible light lasers for metal processing.

With the output power of a single laser diode ranging from milliwatt to multi-watt levels, power can be scaled up by combining single emitters into laser diode bars and stacks of bars, and a standard bar has a width of 1cm. For decades, there was strong competition between companies to increase the output power of diode bars, and an exponential growth trend was seen. While commercial diode bar products usually offer power less than 200W per diode bar at 1μm wavelength, R&D divisions of laser manufacturers have demonstrated continuous wave (CW) average power exceeding 1kW per bar.

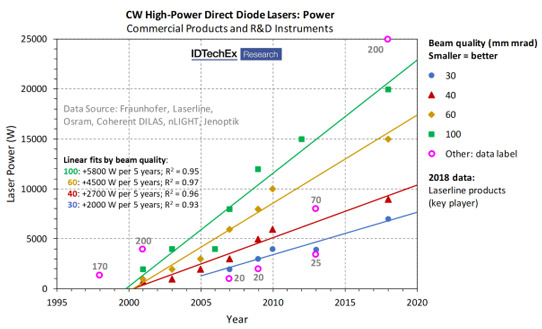

Picture: Evolution of output power and beam quality in high-power direct diode lasers (HPDDLs) at 1 micron infrared wavelength, according to data collected and analysed by IDTechEx. HPDDLs are a rapidly evolving tool for material processing and industrial manufacturing.

Increasing diode bar power has enabled new applications in material processing, but some emerging applications demand the enhancement of laser parameters like wavelength stability and device lifetime. Therefore, competing on power is no longer the priority for companies in this market. The ongoing evolution of diode laser technology includes the improvement of infrared beam quality for precision engineering and the development of novel visible light lasers for metal processing.

Power and precision: emerging direct-diode laser technologies

The advances in semiconductor laser technology enable the development of direct-diode lasers (DDLs), including high-power direct-diode lasers (HPDDLs) that produce multi-kilowatt output power. DDLs combine numerous diode bars with beam-shaping optics, control electronics and a cooling unit. Technology advances now enable DDLs to generate output power exceeding 20kW in multi-mode systems and produce multi-kilowatt power at higher beam quality than before. In addition to DDLs, companies like Germany’s Laserline offer diode lasers coupled to active fiber converters, which produce 4-6kW output power at a beam quality of 4-6mm.mrad.

Dramatic improvements in beam quality now enable users to focus laser light to a small point, and this revealed DDLs as rapidly evolving tools for processing metal, plastic and composite materials. In applications like laser welding which require high precision and deep penetration, DDLs can now compete with fiber lasers. While DDLs directly convert electricity to laser light, fiber lasers are based on rare-earth metal doped optical fibers which must be optically pumped with energy input from laser diodes or diode bars.

The unit price of a DDL is significantly lower than a fiber laser for CW output power up to 1kW. In 2018, the typical unit prices were $20,000 for a 1kW HPDDL and $25,000 for a 1kW fiber laser, as quoted by key player companies interviewed by IDTechEx. The difference in price between DDLs and fiber lasers is larger at sub-kilowatt output power. Additionally, the wavelengths offered by DDLs are different to fiber lasers, which means that DDLs can process materials with matching absorption spectra more efficiently.

Consequently, DDLs and HPDDLs are emerging as major global trends in industrial manufacturing. To enhance their position in high-growth DDL/HPDDL markets, key players are making strategic acquisitions and investing in production capacity expansion. For example, Japan’s Panasonic acquired US-based laser company TeraDiode for its expertise in HPDDLs that generate high-quality beams via a patented optical process.

Overall, the technology advances outlined above provide excellent business growth opportunities, believes IDTechEx.

Welding and 3D printing copper with bright blue diode lasers

A particularly important trend is the development of blue direct-diode lasers for applications like welding and 3D printing copper, with Laserline launching a 1kW product in 2019. Blue laser light is faster and more efficient at processing metals that are poor absorbers of the 1μm infrared radiation produced by most industrial laser systems.

In 2018, Japan’s Shimadzu commercialized the BLUE IMPACT diode laser, which produces 100W of power at high brightness. This was developed in collaboration with Osaka University as part of a Japanese national project. The BLUE IMPACT laser combines many gallium nitride (GaN) blue laser diodes made by Nichia, which have doubled in efficiency and increased by an order of magnitude in output power since 2006.

A key application of Shimadzu’s 450nm blue diode laser is in 3D printing copper. High absorption of blue laser light by copper enables a fast process with reduced back reflections, which are serious challenges for conventional infrared lasers. The newly developed 3D printer can efficiently print objects using pure copper powder. Existing 3D printer technologies typically use copper alloys like the CuCr1Zr instead of pure copper.

IDTechEx expects rapid adoption of blue DDLs in copper processing from 2019 onward as more products are commercialized.