- News

6 September 2018

Technology advances paving way for micro-LED cost reduction in high-volume applications

© Semiconductor Today Magazine / Juno PublishiPicture: Disco’s DAL7440 KABRA laser saw.

Micro-LED technologies are improving rapidly and new technology paths are emerging at a rapid pace, notes market research and strategy consulting firm Yole Développement in its report ‘MicroLED Displays 2018’. The challenge is now focused on cost reduction. What is the feasibility of each solution? Can micro-LED TV or smartphone display manufacturing costs be compatible with these applications? Which cost reduction paths are the most realistic?

“Technology advancements pave the way for various cost-reduction paths toward volume manufacturing, but none are straightforward,” comments senior market & technology analyst Dr Eric Virey.

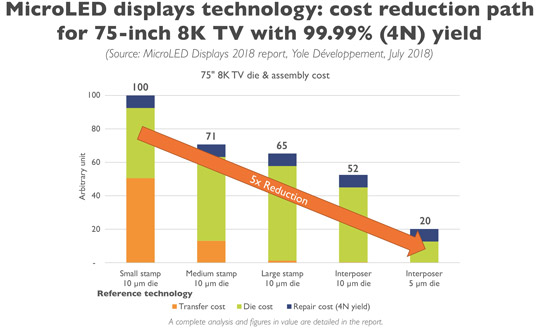

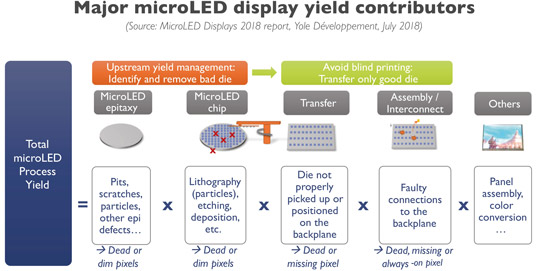

Dozens of technologies are being developed for micro-LED assembly and pixel structures. The cost and complexity range can be staggering. However, there are some fundamentals that anchor all those processes. Alignment dominates assembly cycle times, die size cannot get infinitely small, epitaxy cost has already been through more than 20 years on the cost reduction curve. Cost analysis therefore allows companies to narrow the process parameters down to economically realistic windows and identify efficient cost-reduction strategies.

“Micro-LED companies must understand the cost targets for each application and work backward, making process choices and developing each step so it fits the cost envelope,” asserts Virey. “Processes that cannot deliver the right economics will disappear. If none can deliver the right economics, the opportunity will never materialize,” he adds. “MicroLED is entering the valley of death between technology development and industrialization and commercialization.” Technology solutions should start converging by the end of 2019, it is reckoned.

As the technology improves, there are credible cost-reduction paths for micro-LEDs to compete in the high-end segment of various applications such as TV, augmented reality and virtual reality (AR/VR) and wearables, says Yole. With the right approaches, assembly cost could become a minor contributor. For smartphones, however, approaching the cost of organic light-emitting diodes (OLEDs) implies pushing micro-LEDs toward what is likely to be the limits of the technology in term of die size.

To succeed, micro-LEDs must count on some level of price elasticity, says Yole. They must deliver performance and features that no other display technology can offer and that are perceived by the consumer to be highly differentiating. Micro-displays for AR and head-up displays (HUD) will be the first commercial applications, followed by smartwatches. TVs and smartphones could follow 3-5 years from now, forecasts Yole.