- News

31 January 2018

Mitsubishi Electric’s new 6.5kV full-SiC power module achieves record power density

© Semiconductor Today Magazine / Juno PublishiPicture: Disco’s DAL7440 KABRA laser saw.

Tokyo-based Mitsubishi Electric Corp says that, among power semiconductor modules rated 1.7-6.5kV, its newly developed 6.5kV full silicon carbide (SiC) power semiconductor module is believed to offer record power density of 9.3kVA/cm3, which is 1.8x the 5.1kVA/cm3 of a conventional silicon insulated-gate bipolar transistor (IGBT) module (the new full-SiC power module will be compatible with Mitsubishi Electric’s HV100-series silicon IGBT modules).

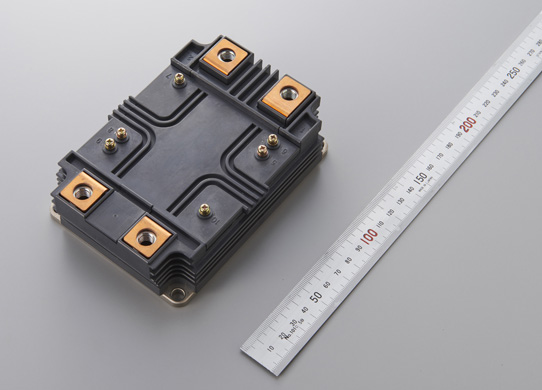

Picture: Prototype 6.5kV full-SiC power semiconductor module.

Mitsubishi Electric is replacing its conventional silicon power semiconductor modules with more energy-efficient SiC power semiconductor modules as key components for power electronics equipment. Previously, the firm commercialized a traction inverter using 3.3kV full-SiC power semiconductor modules for railcars in 2013.

Conventionally, power circuits use two power semiconductor modules connected in series, which requires high voltage in excess of the modules’ rated voltages. The new single module, with a higher rated voltage, significantly simplifies the circuit. Also, replacing silicon IGBT modules with full-SiC modules substantially reduces switching loss (cutting power loss by a third). In addition, operating frequency can be increased (by four-fold) to allow smaller peripheral components, leading to more compact equipment.

As well as enabling higher operating frequencies, full-SiC technology improves the power density and efficiency for smaller and more energy-efficient high-voltage power electronics equipment, says Mitsubishi Electric.

The record power density is made possible by the innovative structure, with integrated metal-oxide-semiconductor field-effect transistor (MOSFET) and diode on a single chip (drastically reducing the chip area). Conventional power semiconductor modules use two separate chips (a MOSFET and a diode). Integrating the diode in the MOSFET chip drastically reduces the module’s footprint.

In addition, newly developed package includes a new insulating substrate capable of high thermal conductivity and high heat tolerance has been adopted (the result of a cooperative effort involving four material manufacturers). Die bonding to the insulating substrate is achieved using Mitsubishi Electric’s own reliable technology.

Power electronics equipment is used widely in consumer appliances, industrial machinery and railcars, all of which are trending toward higher energy efficiency, reduced sizes and high voltages. Mitsubishi Electric therefore expects the new module to lead to smaller and more energy-efficient power electronics equipment for high-voltage railcars and electric power systems.

Development of the 6.5kV full-SiC power module has been supported by a project subsidized by Japan’s New Energy and Industrial Technology Development Organization (NEDO). In addition to the four material manufacturers (DOWA Electronics Materials Co Ltd, Mitsubishi Materials Corp, Denka Co Ltd and Japan Fine Ceramics Co Ltd) project partners also include three universities (Tokyo Institute of Technology, Shibaura Institute of Technology, and Kyushu Institute of Technology) and one public research institute (National Institute of Advanced Industrial Science and Technology).

The number of patents pending for the technology amount to nine in Japan and three outside Japan. Going forward, Mitsubishi Electric says it will continue to further develop the technology and conduct further reliability tests.

Mitsubishi Electric launching 3.3kV, 1500A inverter with all-SiC power module for high-power trains

Mitsubishi Electric SiC power modules

www.mitsubishielectric.com/semiconductors/products/powermod