- News

18 January 2018

LG Innotek develops flip-chip LED package allowing stable 220lm/W efficiency

© Semiconductor Today Magazine / Juno PublishiPicture: Disco’s DAL7440 KABRA laser saw.

Seoul-based materials and component manufacturer LG Innotek (a subsidiary of South Korean electronics company LG Group) has developed an advanced flip-chip LED package that demonstrates high efficiency and high luminous flux without any deterioration in performance, even after completing the 300℃ soldering process.

The firm says that, for the last three years, its flip-chip LED has drawn attention from the back-light unit (BLU) industry as a high-power LED light source because the chip’s electrode is directly attached to the top surface of the PCB substrate without using a connection wire, preventing wire disconnection and ensuring excellent heat dissipation.

The existing flip-chip LED packages were commercialized only as high-power LED light sources in chip-scale package (CSP) form, in which reflective white resin is omitted and the process is relatively simple. However, the existing packages distributed in marketplace have a critical problem that the bonding between the chip and the substrate melts, dislocating the chip and reducing brightness by about 10% when exposed to high temperature.

With the existing flip-chip LED packages (with reflective white resin) it was difficult to ensure the quality of light, as the temperature of some of the processes for producing lighting modules and finished products reaches 250℃ or more.

The new high-quality flip-chip LED package produces high efficiency of 220 lumens per watt (lm/W) stably because the bond between the chip and the substrate does not melt even at a temperature of 250-300℃. Lighting companies can hence use the flip-chip LED package to produce premium bulbs, tubes and flat-panel lighting without sacrificing light quality, says LG Innotek.

The firm developed the new flip-chip LED package by improving the internal structure of the package, designing its own production process, and enhancing the existing flip-chip mounting technology. The chip’s internal structure is also newly designed, with proprietary technology maximizing the efficacy and heat dissipation performance.

In addition, LG Innotek focused on quality and conducted a reliability test of more than 6000 hours. The resultant ‘high-quality flip-chip LED package’ achieved stable performance even when subjected to high-temperature thermal shock at the request of a customer. Due to the strict quality verification process, it took two years to develop the product, which is considerably longer than the period required for the development of general LED packages, notes the firm.

LG Innotek applied for 65 new technology patents during the development process. It says it has taken thorough measures not only to secure its proprietary core technologies but also to help customers to focus on manufacture and sales of the modules and finished products without worrying about patent disputes related to the light source.

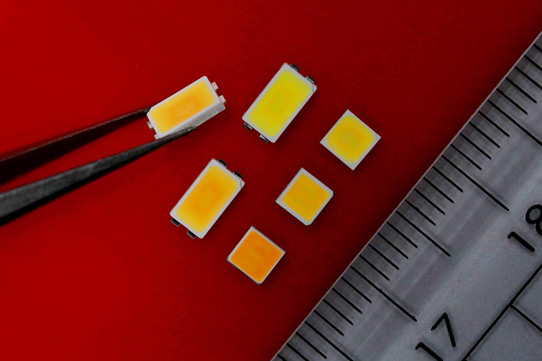

The company has established a product lineup of high-quality flip-chip LED packages that can be customized according to lighting application. The main family consists of mid-power, high-efficiency models for mid-power applications at each color temperature, such as 220lm/W class-5630 3V products and 215-lm/W class-3030 3V products.

In particular, LG Innotek has strengthened its high-power and high-luminous-flux product lineup with 6V, 9V and 12V flip-chip LED packages in series two and/or two in parallel in the 3030 product family, which were previously difficult to manufacture due to the package design and processing limitations.