- News

2 August 2018

Amber light for zinc tin nitride boost from indium gallium nitride wells

Md Rezaul Karim and Hongping Zhao of Ohio State University in the USA are proposing the use of zinc tin nitride (ZnSnN2) as a means to improve the efficiency of indium gallium nitride (InGaN) light-emitting diodes (LEDs) at longer wavelengths in the amber 600nm range [J. Appl. Phys., vol124, p034303, 2018]. Although the work is theoretical, professor Zhao heads up a laboratory with access to a range of metal-organic chemical vapor deposition (MOCVD), low-pressure chemical vapor deposition (LPCVD) and chemical vapor deposition (CVD) equipment (https://u.osu.edu/zhao2592/).

InGaN LEDs need higher indium compositions to create the narrower bandgaps required to access longer wavelengths. Unfortunately, indium is more volatile than gallium in III-nitride growth processes. To maintain indium in the crystal structure, growth temperatures must be kept relatively low, reducing quality.

At the same time, differences in the charge polarization of the III-nitride bonds lead to large spontaneous and strain-dependent (piezo-) electric fields that tend to separate electron and hole wavefunctions, impeding recombination into photons. A further problem with high-indium-content InGaN is a tendency for phase separation, creating uneven distributions of indium concentration.

Karim and Zhao see ZnSnN2 as a means of confining holes within InGaN quantum well (QW) structures, based on a 1.4eV valence-band offset between the materials, according to “recent first principles calculations”. At the same time, the conduction-band offset is relatively small at -0.3eV.

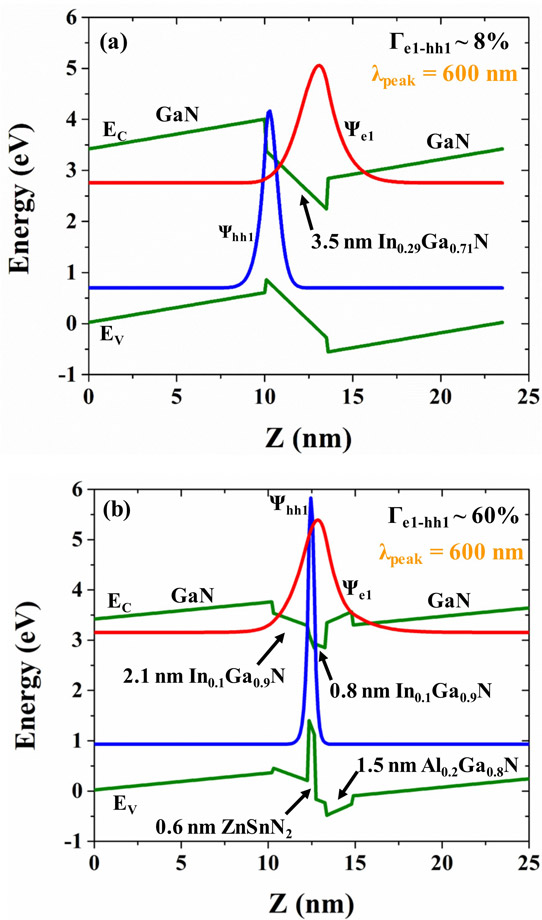

The hole confinement is predicted to increase the overlap with the electron wavefunction on the basis of self-consistent 6-band k.p calculations (Figure 1), compared with an InGaN QW without ZnSnN2. Improved overlap should lead to more efficient conversion of the electrons and holes into photons. In addition, the reduced indium component (10% versus 29%) should enable higher growth temperatures and hence better heterostructure quality.

Figure 1: Energy-band alignment, and electron and hole wavefunctions, for first confined energy states in (a) conventional GaN/InGaN/GaN and (b) GaN/InGaN/ZnSnN2/InGaN/AlGaN/GaN QWs. The thin aluminium gallium nitride (AlGaN) layer improves electron confinement in the QW active region.

Some theoretical work involving professor Zhao at Case Western University in Ohio on InGaN QWs containing zinc germanium nitride (ZnGeN2) layers demonstrated increases in radiative efficiency for blue (485nm) and green (530nm) light emission [Lu Han, Kathleen Kash, and Hongping Zhao, Appl. Phys., vol120, p103102, 2016]. Germanium is situated in the same ‘Group IV’ column of the periodic table as tin. The ZnGeN2 valence-band offset was ~1.1eV, but a large conduction band offset tended to reduce the electron-hole wavefunction overlap.

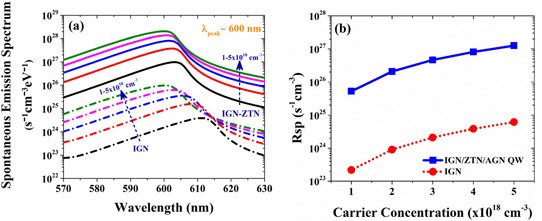

Figure 2: (a) Spontaneous emission spectra and (b) spontaneous emission radiative recombination rates of IGN and IGN-ZTN QWs for a range of carrier concentrations.

Karim and Zhao’s further calculations (Figure 2) suggest that InGaN-ZnSnN2 (IGN-ZTN) QWs would have 210-250x enhancement over conventional InGaN QWs for the peak intensity for spontaneous emission of 600nm-wavelength light. Both structures show some blue-shift as the carrier concentration increases from 1x1018/cm3 to 5x1018/cm3 due to screening effects, but the IGN-ZTN shift is only 3nm, compared with 11nm for the conventional IGN QW. Integrating the spontaneous emission over the spectral range gives a 210-235x enhancement of the IGN-ZTN QW emission over that of the conventional IGN structure.

Karim and Zhao comment: “Note that the internal quantum efficiency (IQE) of LEDs is determined by the ratio of radiative recombination rate and the total recombination rate which includes both the radiative and non-radiative components. Here, if we take into account the expected lower non-radiative recombination in the IGN-ZTN QW, one can expect even larger enhancement of the IQE from the novel QW design.”

ZnSnN InGaN LEDs MOCVD LPCVD CVD

https://doi.org/10.1063/1.5036949

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.