- News

23 February 2017

LayTec's EpiNet 2017 software enables in-situ wafer bow measurement in multi-pocket satellite configuration

In-situ metrology system maker LayTec AG of Berlin, Germany says that the new release of its control and analysis software EpiNet 2017 provides a solution for the problem that, while in-situ reflectance and temperature on a multi-pocket satellite susceptor can be measured very accurately, in-situ curvature monitoring is trickier because it is rather challenging to find the wafer center.

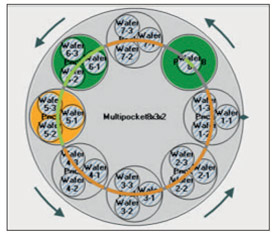

Figure 1: Configuration panel of EpiNet 2017 showing test run configuration: Pocket 5 - 3x2", Pocket 6 - 3x2", Pocket 8 - 1x2" reference wafer, all other - dummy wafers.

Figure 1: Configuration panel of EpiNet 2017 showing test run configuration: Pocket 5 - 3x2", Pocket 6 - 3x2", Pocket 8 - 1x2" reference wafer, all other - dummy wafers.

Figure 1 shows the susceptor layout for a gallium nitride (GaN)/sapphire run performed at Ferdinand-Braun-Institut, Leibniz-Institut für Höchstfrequenztechnik (FBH) of Berlin, Germany. Pocket #8 was loaded with a single 2" reference wafer. Pockets #5 and #6 contain three 2" wafers each. Pockets #1–4 and 7 have dummy wafers.

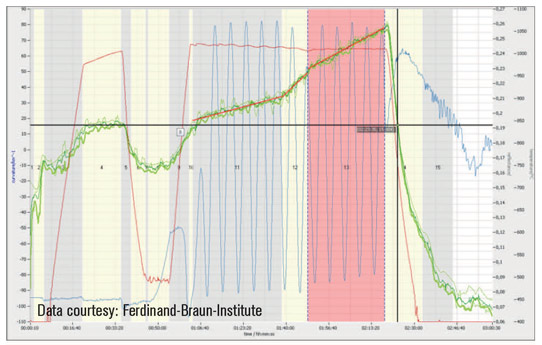

In Figure 2, the wafer bow signals of the pockets loaded with epitaxial wafers are compared. The values of the multi-pockets comply nicely with those of the single-pocket, says LayTec. Analytical functions for wafer bow such as curve slope (marked by a red line) work well for both single- and multi-pocket.

Figure 2: In-situ measurements of GaN/sapphire run (standard buffer growth on sapphire as used for LEDs): green transients - curvature signals; red – temperature; blue - reflectance. Curvature signals of the three loaded pockets (as described in Figure 1) are in good compliance. The signal-to-noise ratio stays within spec also on multi-pocket satellites.

In addition, the signal-to-noise ratio (SNR) of the measurements on multi-pockets (shown without filtering) stays within spec (like that of the single-wafer pocket).