- News

2 October 2015

Trumpf opens Berlin high-power laser diode engineering subsidiary

Laser manufacturer Trumpf has opened a new subsidiary in Berlin for the engineering of laser diodes. In close proximity to, and in close cooperation with, the Ferdinand-Braun-Institut, Leibniz-Institut für Höchstfrequenztechnik (FBH) and other facilities and experts, the firm aims to continue expanding its technology in the high-performance diode laser sector (for use both as a pump source and as a direct diode laser). The close cooperation between industry and research is intended to make Trumpf's laser systems more energy-efficient.

"The Berlin subsidiary, with its initial staff of ten people and the joint ventures emanating from it, is of crucial importance for our development work on this key future topic," says Dr Berthold Schmidt, head of the central department for R&D at Trumpf. "We are attempting to look ten years ahead here, and to lay the foundations for future applications, " he adds.

"We are looking forward to cooperate directly with Trumpf in the active Berlin research landscape, " comments FBH director professor Günther Tränkle. "The joint venture underlines the capability of our FBH teams, as well as the desire, even of major players, to maintain and further extend their market lead with our assistance."

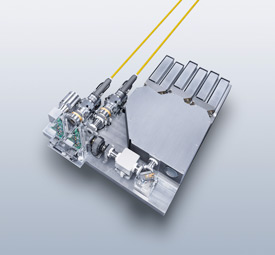

Picture: Trumpf's TruDiode 6006 lasers.

Picture: Trumpf's TruDiode 6006 lasers.

Trumpf and the FBH have already worked together on high-power diode lasers for several years. Trumpf also funds several PhD studentships at FBH. "Over the past years our research activities have resulted in numerous patents, enabling further improvements to diode lasers," notes Tränkle. "The demand is there and will continue to grow, because the market for laser systems that can process and cut metals is vast." For some materials, such as the tempered steel used in the manufacture of monocoque safety cells in cars, the laser is virtually unrivaled, and has long since become an indispensable tool in production, says Trumpf.

"For cutting thick sheet metal, a very powerful laser beam is required," notes Dr Stephan Strohmaier, who runs Trumpf's Berlin subsidiary. "Our goal is to efficiently combine ever more laser power inside an ever more brilliant beam," he adds. In terms of power density and power-to-light conversion rate, diode lasers from FBH and Trumpf are currently among the most powerful in the world, it is claimed, and new records are frequently being set in the laboratories. The Berlin Trumpf subsidiary - which not only has capabilities in semiconductor laser physics, mounting technology, design and simulation but also has its own cleanroom facilities - will drive development further.

Trumpf notes that, not only do diode-pumped solid-state lasers and direct-diode lasers have particularly high efficiencies (30-40% or more), they also save on water and energy, and their compact design makes them material-friendly as well as comparatively cheap. With direct-diode lasers, the laser radiation of several diodes is combined by using optic elements to create a beam of increasingly better focusability. This combination beam (just one tenth of a millimeter in diameter) can then be used to cut metals such as steel in the automotive and shipbuilding industries.