- News

16 June 2014

Arkansas researchers design SiC-based ICs operable at over 350°C

Researchers at the University of Arkansas have designed integrated circuits that can survive at temperatures greater than 350°C (about 660°F). Funded by the US National Science Foundation (NSF), their work could improve the functioning of processors, drivers, controllers and other analog and digital circuits used in power electronics, automobiles and aerospace equipment – all of which must perform at high and often extreme temperatures.

“This ruggedness allows these circuits to be placed in locations where standard silicon-based parts cannot survive,” says Alan Mantooth, distinguished professor of electrical engineering (holder of the Twenty-First Century Chair in Mixed-Signal Integrated Circuit Design and Computer-Aided Design in the College of Engineering). “The circuit blocks we designed contributed to superior performance of signal processing, controllers and driver circuitry,” he adds.

Picture:

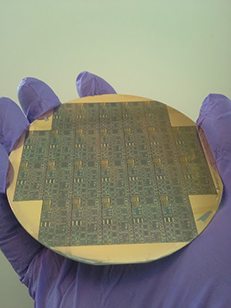

The SiC wafer contains more 1000 individual circuits.

Picture:

The SiC wafer contains more 1000 individual circuits.

One-third of all power produced in the USA passes through some kind of power electronic converter or motor drive before it reaches the end-user. Circuits developed by the team could enable tight integration of control in the tough environmental conditions these applications demand as well as improving electrical efficiency while simultaneously reducing the overall size and complexity of these systems.

The researchers worked with silicon carbide (SiC), which can withstand extremely high voltage and is a good thermal conductor, so it can operate at high temperatures without requiring extra equipment to remove heat.

Led by Mantooth and Jia Di, professor of computer engineering, the team achieved the higher performance by combining SiC with wide temperature design techniques. In power electronics and integrated circuits, the work is reckoned to represent the first implementation of a number of fundamental analog, digital and mixed-signal blocks, such as a phase-locked loop (PLL) using a complementary-style SiC technology. A PLL is a control system that generates an output signal whose phase is related to the phase of an input signal. Such a function is critical in circuit applications such as signal synchronization, frequency synthesis, and modulation and demodulation schemes.

The research was part of the NSF’s Building Innovation Capacity program, which is designed to partner university and industry research to build intellectual collaborations so that innovations flow from ideas to solid research results, company prototypes and products. The basis of this innovation ecosystem is the University of Arkansas and two Fayetteville technology firms, Ozark Integrated Circuits (which develops ICs for remote sensing and actuation under extreme environmental conditions) and Arkansas Power Electronics International Inc (APEI) of Fayetteville, AK (which specializes in high-performance electronics for applications including defense, aerospace and hybrid/electric vehicles). Raytheon is also a key partner.

Ozark Integrated Circuits is commercializing the circuit technology. Arkansas Power Electronics International focuses on using the circuits in power applications.

The research funding was awarded to Arkansas Circuit Design Center (which consists of two laboratories, one directed by Mantooth and one by Di). It supports the mission of the University of Arkansas’ National Center for Reliable Electric Power Transmission, which is funded as part of the federal government’s focus on R&D on smart-grid and renewable technologies. The center is one of just a few university-based research centers investigating electronic systems to make the USA’s power grid more reliable and efficient. The US Department of Energy has funded the center since 2005 because of the university’s research expertise in advanced power electronics and long-term investigation of silicon carbide. Mantooth is executive director of the center.