- News

11 September 2013

Fraunhofer IAF and FBH boost GaN voltage converter efficiency to 98%

To increase the efficiency of voltage converters and minimize heat losses, researchers at the Fraunhofer Institute for Applied Solid State Physics IAF in Germany are developing transistors based on gallium nitride, characterized by low on-resistance and high switching speed. Voltage converters have recently achieved an efficiency level of 98% – this saves energy in electro-mobility and photovoltaics.

In order to foster the development of electro-mobility it is essential to reduce the energy consumption caused by electric cars, says Fraunhofer IAF. Efficient voltage converters can minimize losses and thus save energy during operation and the charging of batteries.

Now, researchers at Fraunhofer IAF and the Ferdinand-Braun-Institut (FBH) in Berlin have managed to develop GaN devices for applications in electro-mobility and photovoltaics where the efficiency of the transistors in the voltage converters has been increased to 98%. Practical tests have shown a performance of up to 1kW. “We have closed the gap to the international state-of-the-art,” says Dr Michael Schlechtweg, head of department at Fraunhofer IAF. In contrast to conventional devices based on silicon, GaN transistors allow losses in voltage converters to be reduced by more than half.

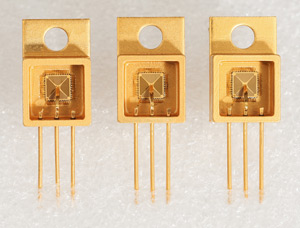

Picture:

GaN transistors for efficient power electronics.

Picture:

GaN transistors for efficient power electronics.

The new devices are the result of the research project ‘PowerGaNPlus’, which was supported by €3m of funding over three years from The German Federal Ministry of Education and Research (BMBF). The funding was part of different R&D projects on the topic ‘Power Electronics for Increased Energy Efficiency’ in the program ‘IKT 2020 – Research for Innovation’. The aim is to establish Germany as the leading provider for technologies of electro-mobility and to contribute to future-oriented mobility. The BMBF hence supports particularly innovative partnerships between science and industry.

Practical tests show robust GaN devices

Regarding the development of GaN technology, Fraunhofer IAF cooperates with Robert Bosch GmbH, among others, to test the real-life behavior of the devices. Stress tests conducted so far have not only shown the devices’ good performance but also gave a first indication of high short-circuit strength. “Validation of the devices developed within the project with a breakdown voltage of more than 600V showed encouraging performance,” says Dr Walter Daves, who supervised the project at Robert Bosch GmbH. “Already in this early development stage, low conduction and switching losses comparable to considerably more mature and commercially available silicon carbide transistors were demonstrated during operation of the gallium nitride devices in circuits ready for application,” he adds. “The stress tests conducted so far have also hinted at high short-circuit strength and thermal stability.” The devices reached maximum currents of up to 100A during on-resistance operation.

The transistors have already been tested for applications in battery chargers for electric cars and (together with inverter manufacturer KACO new energy GmbH of Neckarsulm, Germany) also in photovoltaic inverters. Also cooperating with Fraunhofer IAF in the research project are IXYS Semiconductor GmbH, United Monolithic Semiconductors GmbH, Universität Erlangen-Nürnberg, and RWTH Aachen.

New opportunities for GaN technology

Whereas silicon-based devices are slowly reaching their physical limits, GaN technology offers new opportunities for power electronics, says Fraunhofer IAF. Since GaN devices can be operated under higher voltages and temperatures than conventional power devices based on silicon, this allows a reduction in cooling effort, making compact, light-weight and cost-effective voltage converters feasible. Compared with silicon transistors, GaN allows switching frequency to be increased by at least a factor of three. Also, due to the higher breakdown strength and power density of the material, the devices are considerably more efficient than their silicon equivalent. This will reduce the energy consumed while charging the battery of an electric car or feeding in energy from solar parks into the grid.

“Besides using gallium nitride transistors in electro-mobility and photovoltaics, they will also be able to increase efficiency and save energy in household applications, production technology or in generators for plasma and laser systems,” says Dr Patrick Waltereit, project leader at Fraunhofer IAF. “Our continuous goal will be to increase reliability, thermal stability and switching frequency in order to use the full potential offered by gallium nitride technology.”