- News

25 June 2013

Hermetic GaN power amplifier package developed by SCHOTT and Tesat-Spacecom used aboard Proba-V satellite

The Electronic Packaging business unit of SCHOTT technology group of Mainz, Germany and Tesat-Spacecom GmbH of Backnang, Germany (a manufacturer of systems and equipment for telecoms via satellite) have developed a hermetically sealed package that can be used in space, and has been supporting the European Space Agency’s mini-satellite Proba-V for performing Earth observations since the beginning of May.

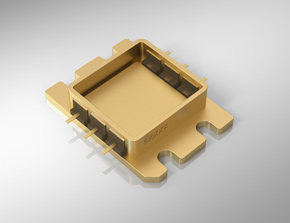

Specifically, for the first time the housing contains a gallium nitride (GaN) power amplifier monolithic microwave integrated circuit (MMIC) chip. SCHOTT and Tesat-Spacecom developed the optimum composition and geometry for the package’s heat-sink. In addition, the package features hermetically sealed HTCC (high-temperature co-fired ceramic) multi-layer ceramics as high-frequency feedthroughs that allow only minimal insertion loss and reflection of high-frequency waves.

The communication system for Proba-V weighs about 140kg, is 1m3 in size and contains a special microwave amplifier based on gallium nitride (used for the first time ever in a European satellite). This is being used to transmit photos (taken at a height of about 800km) in the X-band (at a frequency of 8GHz) to monitor vegetation on Earth. GaN is capable of improving signal strengths and data transmission by 5-10 times and will be used as a high-performance material in communication systems, reckons SCHOTT. The MMIC amplifier chip delivers its performance via a surface area just a few square millimeters in size and hence requires innovative packaging concepts, the firm adds.

Picture:

Package developed by SCHOTT and Tesat-Spacecom features hermetically sealed HTCC multi-layer ceramics as high-frequency feedthroughs. Source: SCHOTT.

Picture:

Package developed by SCHOTT and Tesat-Spacecom features hermetically sealed HTCC multi-layer ceramics as high-frequency feedthroughs. Source: SCHOTT.

The MMIC amplifier chip has been installed inside a hermetically sealed package co-developed by SCHOTT and Tesat-Spacecom. Due to the design of the ceramic-to-metal feedthrough, the high-frequency waves are able to pass the wall of the housing with very low attenuation, so the loss of power (insertion loss) is minimized. In addition, reflection losses of the high-frequency waves along the housing wall are also minimized.

“Simulations of electromagnetic waves have enabled us to determine the best possible geometries and designs for this special type of feedthrough in close coordination with manufacturing technology," explains Dr Thomas Zetterer, development engineer at SCHOTT Electronic Packaging.

The second key property of the package is the high thermal conductivity of its base, allowing dissipation of the heat generated inside the MMIC amplifier. To achieve this, the development teams at SCHOTT and Tesat-Spacecom came up with the optimum material composition and geometry for a heat-sink for this particular application. Materials and material compounds that allow for even higher thermal connectivity still need to be developed in the near future and tested for use in applications with even higher microwave power, say the firms.

“Working together with SCHOTT enables us to obtain the high-thermal-conductivity packages that are urgently needed for future GaN amplifiers," comments Eberhard Möss, group leader at Tesat-Spacecom.