- News

30 April 2013

Fraunhofer demos AlGaN-based sensors for continuous monitoring of UV exposure

Ultraviolet (UV) lamps are used to cure coatings and adhesives in many industrial manufacturing processes, and special sensors are used to measure the intensity of the UV light applied to these surfaces. But because these sensors age too quickly, they can only be used to record intermittent measurements. Now, researchers at Germany’s Fraunhofer Institute have developed a new generation of sensors based on aluminium gallium nitride (AlGaN) that are capable of continuously monitoring UV intensity. The devices will be presented for the first time in Hall 12, booth 537, at the Sensor + Test trade show in Nuremberg (14-16 May).

UV light can be benefi cial, or indeed essential, since the human body needs it to produce vitamin D. Also, industry makes use of UV light, for example to cure adhesives or the coatings applied to food packaging, and to disinfect water. On the other hand, surfaces can be damaged if they are exposed to too much UV light, and poorly regulated UV lamps also waste energy and generate excessive amounts of ozone. UV sensors are therefore used to optimize light intensity.

Usually these sensors are made of silicon or silicon carbide (SiC). The problem with silicon sensors is that they only deliver useful results if external filters are used to exclude visible light from the measurement. Unfortunately, the filters are very expensive and not particularly resistant to UV light. So, to reduce ageing, measurements can only be taken intermittently, as snapshots. Silicon carbide sensors have the advantage of being able to withstand longer exposure to UV light, but they only operate in a narrow spectral band. In most industrial curing processes, it is the longer wavelengths that are of interest – precisely the area in which these sensors are least accurate.

Researchers at the Fraunhofer Institute for Applied Solid State Physics (IAF) in Freiburg have now developed a new UV sensor in collaboration with colleagues at the Fraunhofer Institutes for Manufacturing Technology and Advanced Materials (IFAM), for Optronics, System Technologies and Image Exploitation (IOSB), for Silicon Technology (ISIT) and for Physical Measurement Techniques (IPM). “Our sensor is based on aluminium gallium nitride (AlGaN) technology and can withstand continuous exposure to UV light without damage,” says IAF project manager Dr Susanne Kopta. “This enables it to be used not only for intermittent snapshots but also for permanent inline monitoring,” she adds. A sapphire wafer serves as the substrate for epitaxial growth of the material in the active layers of the sensors.

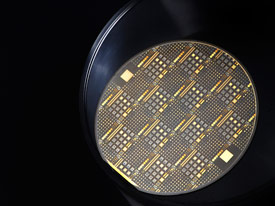

Picture: Processed AlGaN-based UV sensors on a sapphire wafer. Credit: Fraunhofer IAF.

Picture: Processed AlGaN-based UV sensors on a sapphire wafer. Credit: Fraunhofer IAF.

Sensor for high UV intensities

The sensor is particularly suited to applications involving very high UV intensities, and for tasks that require the monitoring of specific spectral ranges. This is due to the fact that the detectors can be set to operate in two different ways. The first option is to define a maximum wavelength threshold. In this case the sensor detects all UV light emitted at wavelengths below the set limit. The alternative is to define two wavelength thresholds, thus cutting out certain parts of the spectrum. “The narrowest range we have been able to achieve is a separation of 20nm,” reports Kopta. This makes it possible to manufacture one sensor for UV-A, another for UV-B, and a third for UV-C wavelengths. The researchers set the wavelengths to be detected by the sensor by varying the ratio of gallium to aluminium in one of the AlGaN layers. Defining this ratio is one of the challenges that the researchers are working on at present.

Another challenge is growing the AlGaN crystal so that it is free of structural defects and impurities. Failure to do so would result in unreliable measurements, because different areas of the sensor would absorb light at different wavelengths. “The hardest part is dealing with the wide range of parameters that affect the manufacture of thin crystal films, which demands a great deal of experience,” says Kopta.

A few demonstration models have already been produced. In the next stage of the project, the researchers aim to optimize crystal growth and obtain more sharply defined wavelength limits. They are also investigating the component durability, with results so far said to be very encouraging. “Initial tests have confirmed that the sensors are capable of operating for 1000 hours under high UV exposure without suffering any damage,” reports Kopta.

UV cameras as a spectrometer or plasma deposition monitor

By placing more than 100 detectors side by side in a strip, a UV camera can be obtained. This device can be used to monitor plasma deposition processes, such as those employed to coat solar cells with an antireflective film. The sensor strip can also serve as a spectrometer. In this case, the UV light is first passed through a diffraction grating, splitting the light into its various spectral components. Each individual sensor detects a specific wavelength and provides information on the intensity of light at that wavelength. The Fraunhofer reckons that this would be a good way of conducting ageing tests on the mercury lamps commonly used for water disinfection or UV curing, e.g. checking if the lamp still emits light of the desired intensity throughout the entire spectrum, or if certain wavelengths are weaker than they should be.