| Home | About Us | Contribute | Bookstore | Advertising | Subscribe for Free NOW! |

| News Archive | Features | Events | Recruitment | Directory |

News

15 October 2010

Nitride wells tune in to green and white

Researchers in France have developed a monolithic nitride semiconductor system for creating and converting blue-violet light into green-yellow [B. Damilano et al, J. Appl. Phys., vol108, p073115, 2010]. By creating a suitable balance of the direct blue-violet and converted green-yellow light, it is possible to create quasi pure-green and even white emission.

Normally white light-emitting diodes are produced by covering a blue or violet LED with a yellow phosphor material such as cerium-doped yttrium aluminum garnet (YAG:Ce). A number of techniques have been proposed to avoid the complication and cost of adding such phosphor layers.

The approach of the researchers from Centre de Recherche sur l’Hétéro-Epitaxie et ses Applications (CRHEA) — which is part of France’s Centre National de la Recherche Scientifique (CNRS) organization — is to use gallium indium nitride (GaInN) multiple quantum wells (MQWs) for both photon emission and conversion.

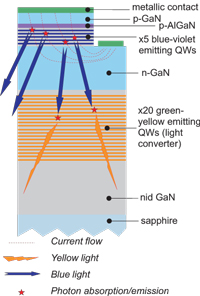

The nitride layers of the color conversion portion of the device (Figure 1) were grown using metal-organic chemical vapor deposition (MOCVD) on c-plane sapphire. The non-intentionally-doped (nid) GaN buffer layer was 6.6μm.

The nitride layers of the color conversion portion of the device (Figure 1) were grown using metal-organic chemical vapor deposition (MOCVD) on c-plane sapphire. The non-intentionally-doped (nid) GaN buffer layer was 6.6μm.

Figure 1: Structure of the device, consisting of a blue LED grown on top of 20-period green-yellow emitting GaInN/GaN MQWs.

The green-yellow MQW color convertor (nid) consisted of a 20-period structure with 3.1nm GaInN wells and 20nm GaN barriers. The last nid GaN barrier layer was somewhat thicker at 300nm. Photoluminescence experiments on the structure showed that its performance was not uniform across the wafer. Near the flat portion of the wafer edge, the emission wavelength was around 500nm (blue-green), but this increased to 580nm (yellow) at the opposite side.

The blue-violet light-emitting layers were grown using molecular beam epitaxy (MBE). The researchers report that a first attempt using MOCVD to grow the active layers was not successful, presumably due to the high temperatures (>900°C) ‘annealing’/disrupting the previous color converter layers.

The n-GaN (silicon doped) layer was 2.2μm grown at 820°C. The active layer was a 5-period MQW with the GaInN well layers grown at 570°C and the GaN barriers at 800°C. The nitride layers were completed with p-type (magnesium doping) layers consisting of a 20nm Al0.1Ga0.9N electron-blocking layer and a GaN layer grown at 760°C. The emission wavelength varied between 405nm at the center of the wafer to 450nm at the edge – these fall within the violet range (380–450nm), bordering on blue (440–490nm).

This epitaxial material was used to create LEDs through normal methods: photolithography, dry (plasma) etch and contact metal deposition. The p contacts were non-transparent nickel-gold, which reflected some light back through the color conversion structure.

Although variations in device properties are not desired in a commercial environment, the researchers used their non-uniformities to study a spread of characteristics. In one group, the active layer emission wavelength (pump) was fixed at 430nm (as determined from devices without color converters grown using the same conditions) — i.e. devices were taken at a fixed radius from the center of the wafer. In another group, the color converter wavelength was fixed at 520nm by taking devices at a fixed distance from the flat edge of the wafer.

At 20mA continuous injection current with a fixed pump wavelength (430nm), it was found that the secondary peak from color conversion reduces by a factor of ~30 as the wavelength increased from 500nm to 580nm. With a fixed color conversion wavelength (520nm) at the same injection current, the shorter wavelength pump of 405nm had a conversion peak ~10x that of a pump with 450nm.

With the 520nm color converter, it was found that the chromaticity coordinates changed from quasi pure-blue (0.168, 0.615) to quasi pure-green (0.148, 0.166) in the move from a 405nm to a 450nm pump. It was also possible to find ‘white’ light-emitting devices on the wafer with a pump wavelength of 406nm and a converter wavelength of 565nm: chromaticity coordinates were (0.328, 0.351); correlated color temperature was 5683K; and color rendering index (CRI) was 41.6. The researchers say that this corresponds to mid-morning/mid-afternoon light. The CRI could be improved (100 is the usual target), the researchers suggest, by increasing the full width at half maximum (FWHM) of the yellow peak, realized by using GaInN color converter QWs emitting at different wavelengths, instead of having identical QWs.

Variation of the light output with current was also studied using a device with a 408nm (violet) pump and 529nm (green) converter. Up to 60mA the chromaticity coordinates stayed approximately constant at around (0.218, 0.498); at 100mA, this shifted to (0.201, 0.429), indicating an increase in the blue component. The researchers interpret the shift as being mainly due to Joule heating effects at larger currents. It is found that the ‘blue’ component red-shifts to 409.3nm at 100mA, which is an effect associated with bandgap narrowing due to heating. The absorption of the light converter decreases with longer pump wavelengths, reducing the green emission. The observed decrease in green emission (~20%) is larger than expected (~14%) — the researchers suspect that the internal quantum efficiency of the converter MQWs also decreases due to heating effects.

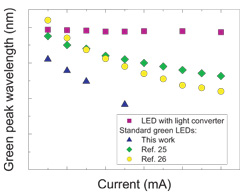

Figure 2: Variation in electroluminescence peak wavelength vs current for standard green LEDs (triangles, diamonds, circles) and for green peak of LED with nitride MQW light converter (squares).

Figure 2: Variation in electroluminescence peak wavelength vs current for standard green LEDs (triangles, diamonds, circles) and for green peak of LED with nitride MQW light converter (squares).

The green peak wavelength of the pump/converter set-up is far more stable compared with LEDs designed to emit green light (Figure 2). Standard LEDs produced using a 520nm converter MQW structure had a blue-shift of 12.7nm over the range 10–50mA, although this is larger than for some reported devices. The pump/converter combination saw a blue–shift of only 1nm in the range 10–100mA.

The researchers suggest that the pumped devices could also produce green light without the large efficiency droops seen in traditional devices — if all the blue photons could be converted to green, then large output power devices would result.

![]() Search: Green-yellow light emitting GaInN MQWs LEDs MOCVD MBE

Search: Green-yellow light emitting GaInN MQWs LEDs MOCVD MBE

Visit: http://link.aip.org

For more: Latest issue of Semiconductor Today

The author Mike Cooke is a freelance technology journalist who has worked in the semiconductor and advanced technology sectors since 1997.