| Home | About Us | Contribute | Bookstore | Advertising | Subscribe for Free NOW! |

| News Archive | Features | Events | Recruitment | Directory |

News

11 February 2010

IBM makes 9.6%-efficient PV cell from earth-abundant materials

The IBM T. J. Watson Research Center, Yorktown Heights, NY, USA has developed a thin-film photovoltaic cell with high efficiency where the key absorbing layer is made entirely of readily available elements (‘High-Efficiency Solar Cell with Earth-Abundant Liquid-Processed Absorber’, Teodor Todorov, Kathleen Reuter and David Mitz, Advanced Materials; DOI: 10.1002/adma.200904155). The new development offers the potential for solar cells to produce more energy at a lower cost, it is claimed.

Existing thin-film solar modules based on compound semiconductors operate with solar-to-electrical energy conversion efficiency of 9–11%. However, says IBM, these are made of materials — such as copper indium gallium selenide (CIGS) or cadmium telluride (CdTe) — that are either costly to produce or contain elements whose scarcity could limit production capacity, or have poor prospects for improving efficiency further (limiting commercialization and wide usage).

“In a given hour, more energy from sunlight strikes the earth than the entire planet consumes in a year, but solar cells currently contribute less than 0.1% of electricity supply — primarily as a result of cost,” says Dr David Mitzi, who leads the team at IBM Research that developed the solar cell. “The quest to develop a solar technology that can compare on a cost per watt basis with the conventional electricity generation, and also offer the ability to deploy at the terawatt level, has become a major challenge that our research is moving us closer to overcoming,” he adds.

To bypass potential supply problems associated with cadmium- or indium-based devices, the aim is therefore to create more affordable solar cells from related compounds of more earth-abundant elements free of indium, gallium or cadmium. However, previous attempts have not exceeded 6.7% efficiency.

To bypass potential supply problems associated with cadmium- or indium-based devices, the aim is therefore to create more affordable solar cells from related compounds of more earth-abundant elements free of indium, gallium or cadmium. However, previous attempts have not exceeded 6.7% efficiency.

In contrast, IBM's new solar cell demonstrates conversion efficiency of 9.6% (40% higher than the value previously attained for this set of materials), comparable with current commercially available thin-film solar cells.

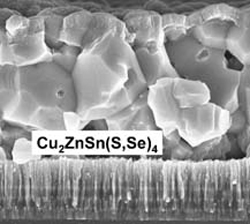

With an absorbing layer consisting of copper (Cu), zinc (Zn), tin (Sn), sulfur (S), and/or selenium (Se), IBM’s ‘CZTS’ solar cell was created using a composite liquid deposition approach that merges the concepts of both solution and nanoparticle-based coating for multinary chalcogenide materials, rather than using prevalent but expensive vacuum-based techniques. IBM expects this change in production technique to enable much lower fabrication costs, as it is consistent with high-throughput and high-materials-utilization based deposition techniques including printing, dip and spray coating and slit casting.

The IBM researchers highlight their solar cell’s potential to accomplish the goal of producing low-cost energy that can be used widely and commercially. In addition, the Cu-Zn-Sn-S-Se compound shows what is claimed to be exceptional phase purity, making such ‘kesterite’ photovoltaic materials suitable for possible commercialization.

The firm adds that, over the past several years, it has pioneered several breakthroughs related to creating inexpensive, efficient solar cells. However, IBM does not plan to manufacture solar technologies. Rather, it is open to partnering with solar cell manufacturers to demonstrate the technology.

![]() Search: IBM Solar cells

Search: IBM Solar cells

Visit: www.ibm.com/research