| Home | About Us | Contribute | Bookstore | Advertising | Subscribe for Free NOW! |

| News Archive | Features | Events | Recruitment | Directory |

| FREE subscription |

| Subscribe for free to receive each issue of Semiconductor Today magazine and weekly news brief. |

News

18 February 2009

Reedholm Instruments introduces first production-ready DC test system for power devices

Reedholm Instruments Co of Georgetown, TX, USA has introduced what it says is the industry’s first DC test system (the RI-2kV/5A) for testing and characterizing power devices at the wafer level in a production environment.

High power devices built on silicon carbide (SiC) and other types of substrates achieve maximum performance with vertical structures connecting the drain or collector to the wafer backside. Testing such devices on manual probers with a collection of instruments is satisfactory during early development, but low yields require reliable, high throughput testing when getting ready for market introduction, says the firm.

A fully integrated DC test system, the RI-2kV/5A is configured for high volume testing. Contact to the wafer backside is through Kelvin sensing leads capable of ± 5A and +2kV, adds the firm. Instrumentation is built into the base of a lost cost, high-speed prober that has been altered to be insensitive to catastrophic device breakdown, and a data driven applications environment eliminates programming. Furthermore, a test controller mounted inside the prober table provides real-time control of instrumentation and prober. The system is accessed via a Windows computer running a test intranet application.

A fully integrated DC test system, the RI-2kV/5A is configured for high volume testing. Contact to the wafer backside is through Kelvin sensing leads capable of ± 5A and +2kV, adds the firm. Instrumentation is built into the base of a lost cost, high-speed prober that has been altered to be insensitive to catastrophic device breakdown, and a data driven applications environment eliminates programming. Furthermore, a test controller mounted inside the prober table provides real-time control of instrumentation and prober. The system is accessed via a Windows computer running a test intranet application.

“The main thing customers have asked for is a simple tool that quickly tests large sample sizes of product die in one probe pass,” said Bill Trimble, Reedholm applications engineer. “They need this to show their customers that they can deliver in high volumes.”

Key features include:

- Integrated system that provides testing and control without programming.

- Fast, automated wafer testing on inexpensive, compact probing platform.

- Rugged rectangular probe card interface that doesn’t require bulky and complicated test head.

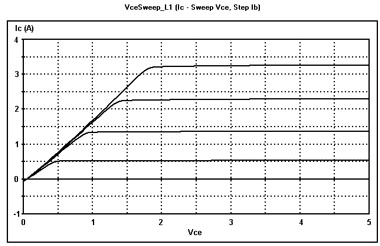

- Bipolar, FET, capacitor, & resistance device parameters and characterization, not just pass/fail.

- 2kV and 5A delivery with errors <0.05% with backside connection to vertical devices.

- 0 to 2kV in <10msec with no overshoot and pulsed 5A tests 30 to 300usec.

- Memory-mapped instrumentation prevents loss of control when device shorts.

- Web browser application running off Microsoft SQL Server database.

- Crystal Reports generated outputs along with Excel compatible CSV & XML exports.

The RI-2kV/5A is now available and can be ordered integrated with an EG 2001 prober or in a separate cabinet for use with another prober.

Visit: www.reedholm.com