| Home | About Us | Contribute | Bookstore | Advertising | Subscribe for Free NOW! |

| News Archive | Features | Events | Recruitment | Directory |

| FREE subscription |

| Subscribe for free to receive each issue of Semiconductor Today magazine and weekly news brief. |

News

17 February 2009

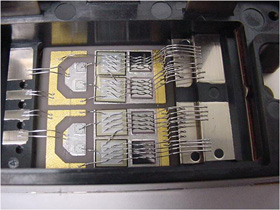

Cree and Powerex develop 1200V, 100A SiC MOSFET-based power switch modules for military systems

Working with both the US Air Force Research Laboratory (AFRL) Propulsion Directorate and Powerex Inc of Youngwood, PA, USA (which supplies discrete, modular and integrated high-power semiconductor solutions), silicon carbide (SiC) power semiconductor maker Cree Inc of Durham, NC has developed a demonstration dual-switch 1200-volt, 100-amp power module featuring all-SiC semiconductors and capable of operating at junction temperatures of up to 200ºC. The combination of SiC devices and innovative package design allows the module to operate at temperatures beyond those achievable with a module based on silicon insulated-gate bipolar transistor (IGBT) technology.

Development of the SiC power module was funded by AFRL. It features Cree’s high-current SiC MOSFETs and Schottky diodes, developed under contracts from the US Army Research Laboratory (ARL). The SiC MOSFETs are normally-off devices and have drive requirements equivalent to the silicon IGBTs they replace, making the SiC module a potential drop-in replacement for most applications. The all-SiC power switch module can be an enabling technology for next-generation military aircraft and future army combat systems, Cree says. The firm adds that the combination of its SiC devices and Powerex packaging technology could also lead to smaller, lighter-weight systems with reduced cooling requirements, while offering increased reliability and overload capacity due to its high-temperature operation capability.

Picture: CR1412 SiC Power Switch.

Compared to a silicon IGBT module of equal rating, and operating at a junction temperature of 150ºC, the SiC MOSFET-based module has 38% lower conduction losses and 60% lower switching losses for a total power-loss reduction of 54% when operated at 20kHz, Cree says. The combination of both low conduction and switching losses suits any application where high efficiency is critical, such as solar energy power inverters and electric drives, and power conversion for hybrid and electric vehicles.

The all-SiC module has been developed using materials and assembly processes common in the industry, offering a clear path to volume production. It can also be easily scaled for higher currents, and the layout can be modified for other switch configurations.

“These 1200V, 100A SiC MOSFET modules represent the next level of integration for SiC power devices... a critical milestone in the technology progression toward high-reliability, energy-efficient power conditioning and control,” claims Dr John Palmour, Cree's chief technology officer, power components and RF devices. “The component-efficiency advantage of this technology is highly relevant in the current energy-conscious environment and could translate to significant energy savings for hybrid and electric vehicles, solar power inverters, and industrial motor drive systems,” he adds.

“As we have seen in the initial reliability-evaluation and electrical-testing of these modules, the practical realization of the SiC high-temperature, power, and frequency performance entitlement, on a pervasive scale, is coming to fruition,” says Dr James Scofield, the power electronics section lead for AFRL’s Propulsion Directorate. “With its inherent high-temperature operational capability, this technology will be widely applicable to high-reliability military and commercial-system power conversion applications.”

![]() Search: Cree SiC MOSFET SiC

Search: Cree SiC MOSFET SiC

Visit: www.cree.com

Visit: www.pwrx.com

Visit: www.afrl.af.mil

Visit: www.arl.army.mil