| Home | About Us | Contribute | Bookstore | Advertising | Subscribe for Free NOW! |

| News Archive | Features | Events | Recruitment | Directory |

| FREE subscription |

| Subscribe for free to receive each issue of Semiconductor Today magazine and weekly news brief. |

News

24 July 2008

AIST claims 17.7%-efficient flexible CIGS solar cell

TechOn Nikkei reports that Japan’s National Institute of Advanced Industrial Science and Technology (AIST) has achieved a conversion efficiency of 17.7% from copper indium gallium diselenide (CIGS), which it claims is one of the highest for a CIGS solar cell on a flexible metal substrate.

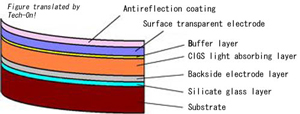

Picture: Schematic view of the solar cell’s structure. The backside electrode layer was formed through the deposition of aluminum. (From TechOn Nikkei.)

By comparison, earlier this year the US National Renewable Energy Labs (NREL) reported that it had achieved a record efficiency of 19.5% for a CIGS cell (nearing the record for multicrystalline silicon cells of 20.3%). However, this was on a glass substrate. NREL’s CIGS cells on flexible metal substrate are 17.1%-efficient.

The carrier density of the p-type semiconductor in a CIGS solar cell is conventionally controlled by adding in an alkali metal such as sodium, in the form of sodium selenide (Na2Se) or sodium fluoride (NaF). However, these are unstable and have poor reproducibility.

The carrier density of the p-type semiconductor in a CIGS solar cell is conventionally controlled by adding in an alkali metal such as sodium, in the form of sodium selenide (Na2Se) or sodium fluoride (NaF). However, these are unstable and have poor reproducibility.

Picture: CIGS solar cell using a ceramic substrate.

Instead, AIST therefore developed the ‘alkali-silicate glass thin layer’ (ASTL) method. First, a silicate glass layer is formed on the substrate. Then, by adjusting the film formation conditions of this silicate glass layer, the amount of alkali metal that passes through the backside electrode layer and diffuses into the light absorbing layer can be controlled. The method therefore increases the reproducibility of adding the alkali metal, significantly improving the conversion efficiency of the solar cell, AIST claims.

AIST tested three kinds of substrate: a ceramic substrate, a transparent plastic film provided by Teijin Ltd, and a titanium foil with a coarse surface. The conversion efficiencies that were achieved were 17.7% with the ceramic substrate, 14.7% with the plastic film, and 17.4% with the titanium foil.

AIST says that it will unveil the details of the technology at the 4th Annual Symposium of Research Center for Photovoltaics next week (28-29 July) at Japan’s National Museum of Emerging Science and Innovation (MeSci) in Daiba, Tokyo.

Thin film to take 28% of PV market by 2012

Thin-film solar market to reach 9GW in 2012

Search: CIGS Flexible metal substrate

Visit: www.aist.go.jp

Visit: http://techon.nikkeibp.co.jp